How to Choose the Right CVT Belt for Your Scooters, ATVs, UTVs and Snowmobiles?

Confused about CVT belt selection? The wrong choice can lead to poor performance and premature failure. Learn how to match the right belt to your vehicle.

CVT belts transfer power in variable-speed drive systems. The right belt depends on your vehicle type, riding conditions, and performance needs. Materials range from standard rubber compounds to advanced aramid-reinforced designs.

Let me share what I’ve learned from years of powersports experience to help you make the best choice for your vehicle.

What Exactly Are CVT Belts? Unpacking Their Role in Powersports Vehicles

Unclear about CVT belt basics? This lack of knowledge leads to poor maintenance decisions. Understand how CVT belts work in your vehicle.

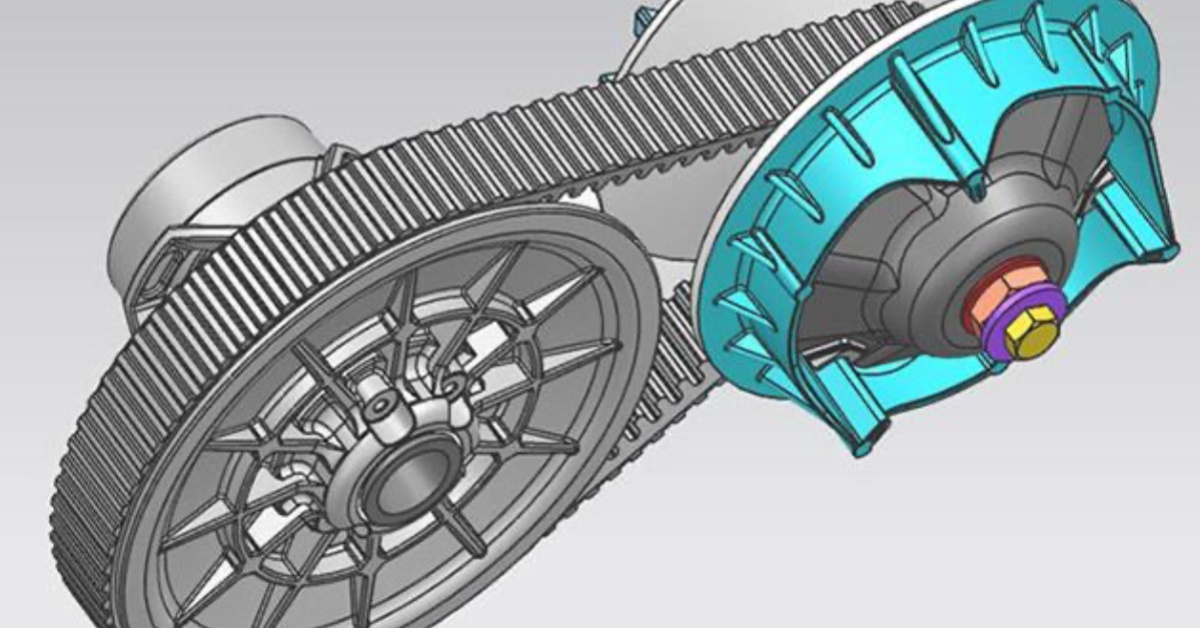

CVT (Continuously Variable Transmission) belts are specially designed drive belts that work with variable pulleys to provide smooth, stepless power delivery. They’re crucial for optimal vehicle performance.

CVT belts are engineering marvels that make powersports vehicles more efficient and enjoyable. Here’s what makes them special:

-

Basic Operation:

- Connects engine to drive system

- Works with expanding/contracting pulleys

- Provides infinite gear ratios

- Delivers smooth power transfer

-

Key Components:

- Top layer (compression layer)

- Cord layer (load-carrying layer)

- Bottom layer (tension layer)

- Side walls (for pulley contact)

-

Working Principles: The belt operates through:

- Variable diameter pulleys

- Constant tension maintenance

- Friction-based power transfer

- Dynamic width adjustment

I’ve seen how proper understanding of these principles helps riders maintain their vehicles better. One rider doubled his belt life simply by understanding how the system works and adjusting his riding style accordingly.

| Component | Function | Impact on Performance |

|---|---|---|

| Top Layer | Compression resistance | Durability |

| Cord Layer | Tensile strength | Power transfer |

| Bottom Layer | Flexibility | Smooth operation |

| Side Walls | Pulley engagement | Efficiency |

How Do Material and Structure Impact CVT Belt Performance?

Overwhelmed by material options? Wrong material choice wastes money and reduces performance. Understand how materials affect performance.

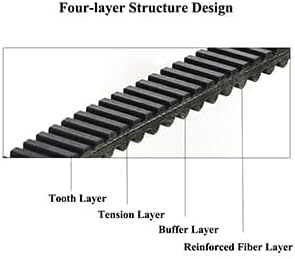

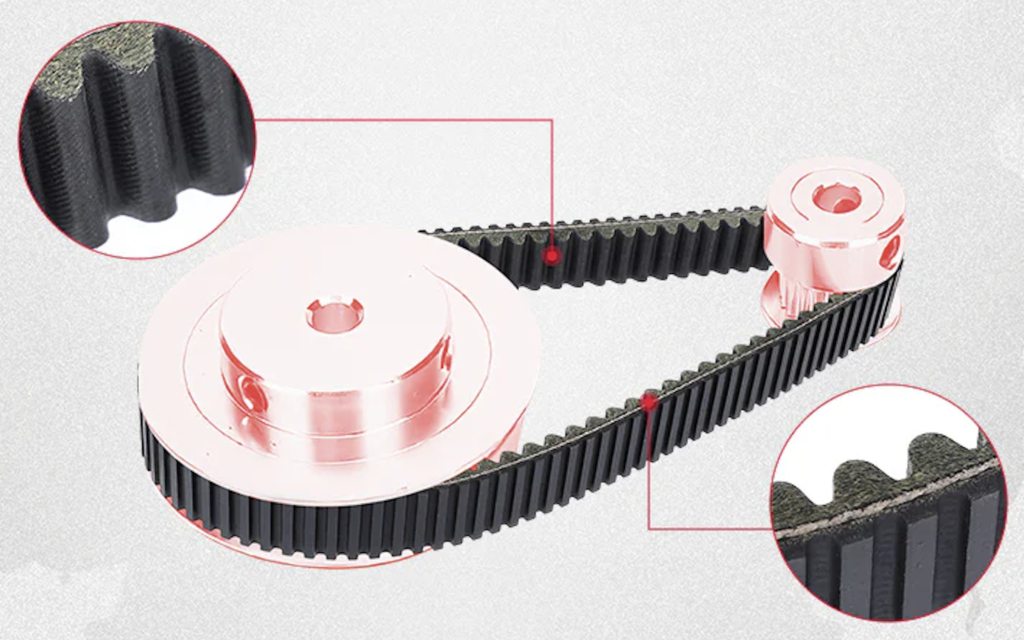

Belt materials range from basic rubber compounds to advanced aramid-fiber reinforcements. Higher-grade materials offer better heat resistance and durability but cost more. Structure affects flexibility and power transfer.

Material selection dramatically influences belt performance and longevity. Here’s my breakdown based on years of testing:

-

Material Types:

- Standard Rubber Compounds: Good for basic applications

- EPDM Compounds: Better heat resistance

- Aramid (Kevlar) Reinforcement: Maximum strength

- Hybrid Materials: Balanced performance

-

Structural Elements:

- Cog Patterns: Affect flexibility

- Cord Angle: Impacts strength

- Side Wall Design: Determines grip

- Overall Thickness: Affects heat dissipation

-

Performance Factors: Each material combination offers different benefits:

- Heat Resistance

- Tensile Strength

- Flexibility

- Wear Resistance

From my experience, matching materials to riding style is crucial. A desert rider needs different belt materials than someone riding in cold conditions.

Which CVT Belt Suits Your Vehicle Best?

Not sure which belt matches your vehicle? Mismatched belts lead to poor performance and safety issues. Learn to match belts to specific vehicles and conditions.

Choose based on vehicle type and usage. Scooters need flexible, heat-resistant belts. ATVs/UTVs require durable, high-strength options. Snowmobiles need cold-resistant materials.

Let’s break down requirements by vehicle type:

-

Scooters:

- Lightweight design

- High flexibility

- Good heat resistance

- Moderate load capacity

-

ATVs/UTVs:

- Heavy-duty construction

- Superior tensile strength

- Excellent heat dissipation

- High shock resistance

-

Snowmobiles:

- Cold weather performance

- Consistent flexibility

- Water resistance

- High torque capacity

I’ve helped many riders upgrade their belts based on specific needs. One ATV rider switched to aramid-reinforced belts for rock crawling and saw significant durability improvements.

| Vehicle Type | Recommended Material | Key Features |

|---|---|---|

| Scooters | Standard Compound | Flexibility |

| ATVs/UTVs | Aramid Reinforced | Strength |

| Snowmobiles | Cold-Rated EPDM | Temperature Resistance |

Still Confused About CVT Belt Selection?

Too many options creating uncertainty? Indecision leads to default choices that might not be optimal. Follow our structured selection process.

Consider your riding style, environment, and budget. Match these to belt specifications. When in doubt, choose slightly higher grade than stock. Factor in maintenance requirements.

Follow this proven selection process:

-

Assessment Factors:

- Riding Environment

- Usage Frequency

- Performance Requirements

- Budget Constraints

- Maintenance Capability

-

Selection Steps:

- Check OEM Specifications

- Evaluate Riding Conditions

- Consider Upgrades

- Review Maintenance Requirements

- Compare Costs

-

Decision Matrix: Create a personal checklist:

- Vehicle Type and Model

- Typical Usage Pattern

- Environmental Conditions

- Performance Goals

- Budget Range

I’ve used this approach countless times to help riders make informed decisions. It prevents expensive mistakes and ensures optimal performance.

Conclusion

Choose your CVT belt based on vehicle type, riding conditions, and performance needs. Consider materials and maintenance requirements for the best long-term value.

SANTE offers a diverse selection of CVT Drive Belts for high-performance off-road vehicles, including ATVs, UTVs, Snowmobiles, and Scooters, with specially formulated rubber compounds and polyester cord or extra-strong aramid (Kevlar) cord. Contact [email protected] for expert guidance.