How to Measure a Timing Belt: The Ultimate Guide for Beginners

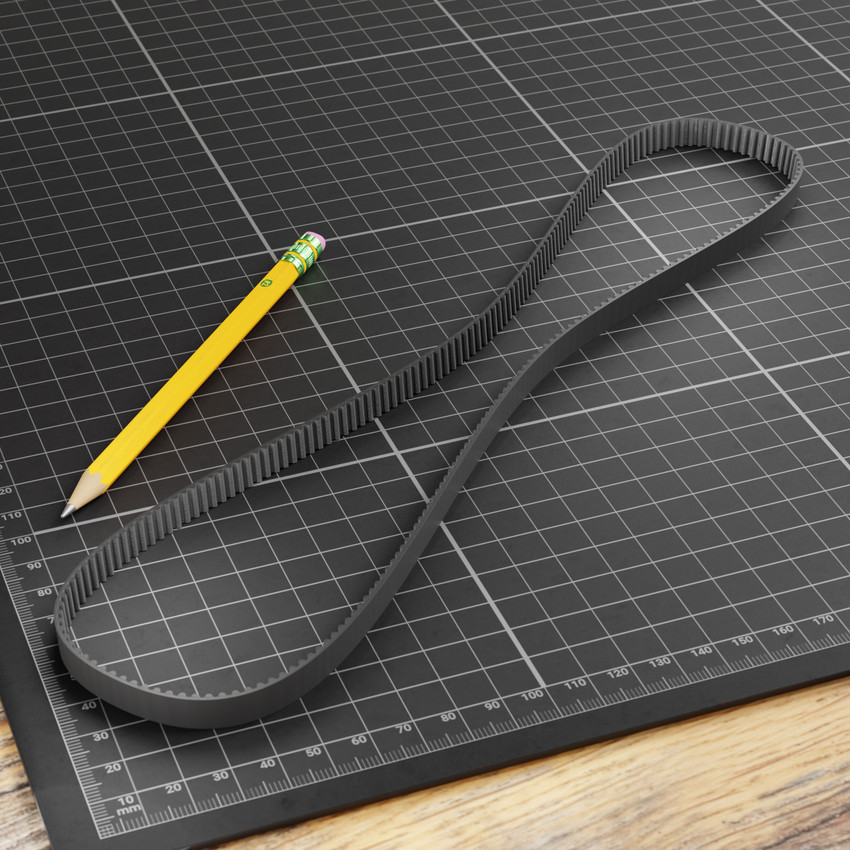

Struggling to measure timing belts correctly? Wrong measurements lead to poor fit and expensive replacements. Learn the proper measurement techniques.

To measure a timing belt, you need to check its length, width, pitch, and tooth profile. Accurate measurements ensure proper fit and optimal performance in your machinery.

I’ve seen many people waste money on wrong-sized belts. Let me show you how to get it right the first time with proper measuring techniques.

How Do You Accurately Measure the Length of a Timing Belt?

Confused about length measurement? An incorrect length causes poor fit and premature wear. Learn the right way to measure belt length.

Measure timing belt length by wrapping a flexible measuring tape around the belt’s outer circumference. For precise results, lay the belt flat and measure the inside length, then add manufacturer specifications.

There are three main methods to measure timing belt length:

-

Outer Circumference Method:

- Wrap measuring tape around the outside of the belt

- Keep tape straight and tension consistent

- Record measurement in millimeters for precision

-

Inner Length Method:

- Lay belt completely flat

- Measure inside length from end to end

- Add manufacturer’s compensation factor

-

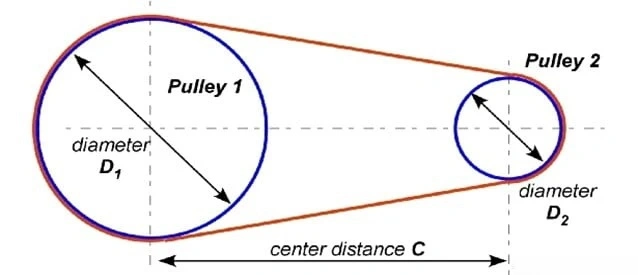

Center Distance Method: When the belt is still installed:

- Measure distance between pulley centers

- Note pulley diameters

- Use formula: Length = 2C + 1.57(D1 + D2) + (D1 – D2)²/4C where C = center distance, D1 = large pulley diameter, D2 = small pulley diameter

I always recommend taking multiple measurements and averaging them for better accuracy. One time, a single millimeter difference caused significant alignment issues in a precision machine.

| Measurement Method | Advantages | Disadvantages |

|---|---|---|

| Outer Circumference | Quick, Simple | Less Precise |

| Inner Length | Most Accurate | Requires Belt Removal |

| Center Distance | Can Measure Installed | Complex Calculation |

What’s the Correct Way to Determine Belt Width and Why Does It Matter?

Uncertain about width measurement? Wrong width affects power transmission and belt life. Master the proper width measurement technique.

Measure belt width at three points using digital calipers. Take measurements from the top surface of the belt, ensuring consistency. Width affects load capacity and proper fit.

Width measurement requires attention to detail and proper tools. Here’s my comprehensive approach:

-

Measurement Points:

- Take readings at the start, middle, and end

- Average these measurements for accuracy

- Check for any variations that might indicate wear

-

Tool Selection:

- Digital calipers provide best accuracy

- Avoid using flexible measuring tapes

- Keep tools clean and calibrated

-

Common Pitfalls:

- Not measuring perpendicular to belt edge

- Including worn edges in measurement

- Using worn or uncalibrated tools

Width accuracy directly impacts performance. I’ve seen belts fail prematurely because they were just 1mm too narrow for the application. The correct width ensures:

- Proper load distribution

- Adequate tooth engagement

- Optimal power transmission

- Extended belt life

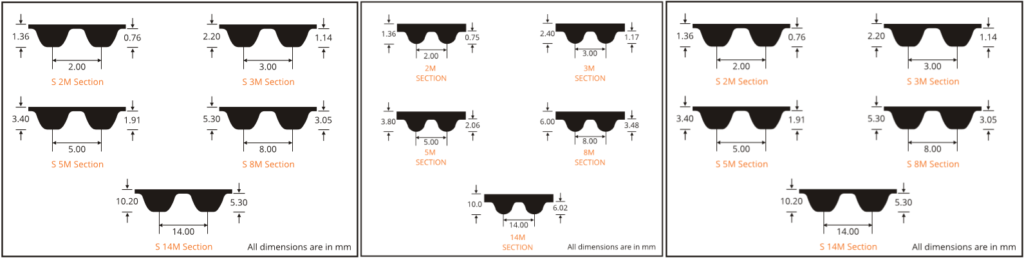

How Can You Identify the Tooth Profile and Pitch of a Timing Belt?

Can’t identify tooth characteristics? Wrong tooth profile causes complete system failure. Learn to identify and measure tooth features.

Count teeth in a 100mm section to determine pitch. Compare tooth shape to standard profiles. Use pitch gauges for confirmation. Document both measurements for replacement.

Understanding tooth characteristics involves several steps:

-

Measuring Pitch:

- Mark a 100mm section

- Count teeth within section

- Calculate pitch (100mm ÷ number of teeth)

- Double-check with pitch gauge

-

Profile Identification:

- Compare to standard profiles (HTD, GT, AT, etc.)

- Check tooth angle and depth

- Note special features like rounded bases

- Document profile code

-

Common Profiles:

| Profile Type | Characteristics | Common Applications |

|---|---|---|

| HTD | Round tooth form | High torque drives |

| GT | Modified curvilinear | Precision machinery |

| AT | Trapezoidal | General purpose |

| XL | Small pitch | Light duty |

I remember troubleshooting a machine that kept destroying belts. The issue? Someone had installed a similar-looking but wrong-profile belt. Understanding profiles prevents such costly mistakes.

What Tools and Tips Can Help You Measure a Timing Belt Like a Pro?

Lack proper measuring tools and techniques? Poor tools lead to inaccurate measurements. Get equipped with the right tools and knowledge.

Essential tools include digital calipers, pitch gauges, and measuring tape. Keep reference charts handy. Document measurements systematically for future reference.

Success in timing belt measurement requires the right tools and approach:

-

Essential Tools:

- Digital calipers (0.01mm accuracy)

- Pitch gauges for various profiles

- Flexible measuring tape

- Profile comparison cards

- Clean workspace with good lighting

-

Professional Tips:

- Take measurements when belt is at room temperature

- Clean belt before measuring

- Document all measurements

- Photograph unusual wear patterns

- Keep detailed records

-

Documentation Method:

| Measurement | Primary Tool | Backup Method | Notes |

|---|---|---|---|

| Length | Measuring Tape | Center Distance | Record both |

| Width | Digital Calipers | Width Gauge | Multiple points |

| Pitch | Pitch Gauge | Manual Count | Verify twice |

| Profile | Profile Cards | Visual Compare | Document code |

From years of experience, I’ve learned that systematic measurement and documentation prevent costly mistakes and streamline future replacements.

Conclusion

Accurate timing belt measurement requires attention to length, width, pitch, and profile. Use proper tools and document everything for successful replacement.

SANTE offers a diverse selection of Timing belts, including Automotive Timing belts and Industrial Timing Belts. Contact us at [email protected] for expert guidance on finding the right timing belt for your needs.