Engine failure is scary and often very expensive. A broken timing belt is a common cause. Understanding why they fail helps you stop this costly problem before it starts.

Timing belt failure usually happens because of age, normal wear, or contamination from things like oil or coolant leaks. Other big causes include incorrect tension (too tight or too loose), pulley misalignment1, or failure of related parts like the tensioner or water pump.

Knowing the general reasons is helpful. But digging into the specific details is much better for avoiding those big repair bills. It’s like knowing bad weather exists, but understanding the difference between a light shower and a major hurricane helps you prepare properly. Let’s look closely at the most common reasons these critical belts break down. Keep reading so you can protect your engines and your business.

What is the main cause of timing belt failure?

Are you worried about an engine suddenly stopping? A failing timing belt is a serious risk for any vehicle or machine. Let’s find out the biggest reason they break.

The main reason timing belts fail is simply age and mileage. Like anything made of rubber and strong cords, they wear out over time and with use. Not replacing the belt on schedule, as the manufacturer recommends, is the single biggest risk.

Think about a timing belt like you think about tires. They work hard under tough conditions. Over thousands of miles and many years, the materials just get tired.

Material Degradation Over Time

Timing belts are usually made from durable rubber compounds reinforced with strong tensile cords (like fiberglass or aramid). Even the best materials degrade. The rubber can become brittle from constant exposure to engine heat. It can develop small cracks, especially on the tooth roots or the back surface. The reinforcing cords inside can stretch or even break down after countless cycles of tension and flexing. This aging process weakens the belt significantly, making it much more likely to snap or lose teeth, especially under stress like hard acceleration or sudden deceleration.

Importance of Replacement Intervals

Vehicle and equipment manufacturers specify [replacement intervals2 for a reason. These intervals are based on extensive testing and are designed to replace the belt before it’s likely to fail. Ignoring these recommendations is gambling with [engine health3 For many cars, this might be every 60,000 to 100,000 miles or every 5 to 7 years, whichever comes first. Industrial equipment will have its own specific schedules based on operating hours or calendar time. As someone sourcing belts, like my customer Andrei in Russia, ensuring the belts you distribute can reliably meet or exceed these intervals is crucial for your brand’s reputation. At SANTE, we design our belts to meet these tough [OEM standards4]

Environmental Impact

The environment inside an engine bay is harsh. Extreme heat is the biggest enemy, accelerating the aging of the rubber. Cold temperatures can also make the belt stiffer and more prone to cracking on startup. Exposure to engine fluids, which we’ll discuss more later, also speeds up degradation. So, a belt operating in very hot climates or under heavy load conditions might need replacement sooner than one in milder conditions.

Here’s a general idea of typical intervals, but always check the specific manufacturer’s recommendation:

| Application Type | Typical Mileage Interval | Typical Time Interval |

|---|---|---|

| Passenger Cars | 60,000 – 100,000 miles | 5 – 7 years |

| Light Commercial Vans | 80,000 – 120,000 miles | 6 – 8 years |

| Industrial Machinery | Varies (Hours/Years) | Check Manual |

| Agricultural Equip. | Varies (Season/Hours) | Check Manual |

Sticking to the schedule is the number one way to prevent age-related failure.

What destroys a timing belt?

Besides just getting old, what actively ruins a timing belt? Certain conditions can cause even a relatively new belt to fail quickly. Let’s look at these belt killers.

Things that destroy timing belts include contamination from engine fluids like oil or coolant, incorrect alignment of pulleys, improper tension (too loose or too tight), and physical damage from debris or failing related parts.

A timing belt needs a clean, stable environment to do its job properly. When outside factors interfere, trouble follows quickly. It’s like trying to run a marathon with rocks in your shoes while someone is spraying oil on the track – it won’t end well.

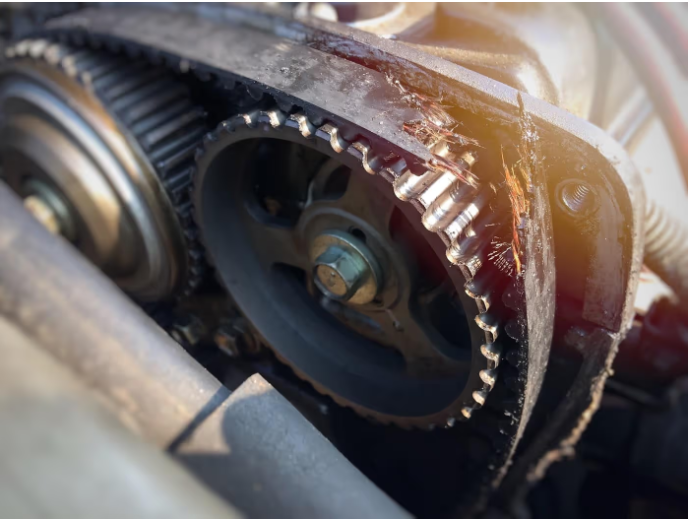

Contamination Damage

Engine fluids are poison to timing belts.

- Oil: Engine oil leaks are common culprits. Oil softens the rubber compounds used in most belts. This makes the belt weak, prone to stretching, and can cause the teeth to deform or shear off. It also makes the belt slippery, increasing the chance of it jumping time.

- Coolant: Antifreeze (coolant) leaks are also damaging. Coolant chemicals can attack the rubber and the reinforcing cords, leading to premature degradation and weakening the belt structure.

- Solvents/Chemicals: Aggressive cleaning agents or other chemicals accidentally sprayed into the engine bay can also harm the belt material.

Alignment Issues

The pulleys and tensioners the timing belt runs on must be perfectly aligned. If a pulley is tilted or offset even slightly, it forces the belt to track improperly.

- Edge Wear: Misalignment often causes the edge of the belt to rub against the flange of a pulley, leading to fraying and shredding of the belt edge.

- Uneven Load: It puts uneven stress across the belt width and on the internal cords, potentially leading to premature failure. You might see wear concentrated on one side of the belt teeth.

Tension Troubles

Correct belt tension is critical. Specialized tools are often needed to set it accurately during installation.

- Too Loose: A loose belt can flap, vibrate excessively, or even jump teeth on the sprockets. This immediately disrupts engine timing, causing poor performance, stalling, or catastrophic engine damage if valves hit pistons. You might hear a slapping noise.

- Too Tight: An overly tight belt puts excessive strain on the belt’s internal cords and structure. It also puts a huge load on the bearings inside the pulleys, tensioner, and components driven by the belt (like the water pump). This can lead to premature bearing failure, which can then cause the belt to fail.

Physical Obstructions

Sometimes, foreign objects can get into the timing belt drive area. A small stone, a broken piece from another engine component, or even a loose bolt can get caught between the belt and a pulley. This can instantly shred the belt or shear off its teeth. Similarly, if a tensioner or idler pulley bearing seizes, it can quickly destroy the belt.

Here’s a quick look at damage types and likely causes:

| Damage Observed | Likely Cause(s) |

|---|---|

| Soft, swollen rubber | Oil contamination |

| Cracked, brittle rubber | Age, excessive heat |

| Frayed belt edges | Misalignment, pulley flange rubbing |

| Sheared teeth | Incorrect tension (loose), debris, shock load |

| Uneven tooth wear | Misalignment, worn sprocket |

| Glazed/shiny back | Excessive tension, seized pulley/tensioner |

| Snapped belt | Age, excessive tension, debris, seized component |

Preventing contamination and ensuring proper alignment and tension during installation are key to avoiding these destructive forces.

What is the number one cause of belt failure?

We’ve talked about age and damage, but what’s the absolute top reason timing belts fail? Understanding this helps focus prevention efforts where they matter most.

The number one cause of timing belt failure is exceeding the manufacturer’s recommended replacement interval. Simply put, most failures happen because the belt was left in service for too long or too many miles, leading to age-related wear and tear.

While other factors like oil leaks or bad tensioners certainly cause failures, they are less frequent overall than simple neglect of scheduled maintenance. It’s a bit like asking why bridges collapse – while design flaws or earthquakes happen, gradual decay from age and lack of maintenance is often the underlying issue.

Neglect vs. External Factors

Think about it from a probability standpoint. Every engine with a timing belt will eventually reach its recommended replacement point. Not every engine will develop a severe oil leak right onto the belt, or have a tensioner fail prematurely (though these components should often be replaced with the belt). Therefore, the risk factor that applies to all belts – age and mileage accumulation – becomes the most common reason for failure when maintenance is ignored. It’s easy to adopt an "if it ain’t broke, don’t fix it" mentality, especially with components hidden from view like a timing belt. But this is very risky.

The Cost of Delay

Delaying timing belt replacement is false economy. The cost of replacing a timing belt (and often the water pump, tensioner, and idler pulleys at the same time, which is best practice) might seem significant. However, it’s minor compared to the potential cost of engine repair or replacement if the belt breaks. In many "interference" engines, a broken timing belt allows the pistons to hit the valves, causing massive internal damage that can cost thousands to fix. I’ve seen customers face huge bills because they tried to save a little by skipping this crucial maintenance.

Importance of Quality Materials and Manufacturing

This highlights why, as a manufacturer, we focus so much on quality. At SANTE, we use high-grade materials and strict manufacturing processes (ISO 9001:2008 and TS-16949 certified) to ensure our belts, like our Raw Edge Cogged V-belts or Timing Belts, are durable and reliable. We know customers like Mark need parts they can trust to last the full service interval. Using a quality belt from a reputable supplier gives peace of mind that the belt itself won’t be the weak link, provided it’s installed correctly and replaced on schedule. Choosing a cheaper, lower-quality belt might save money upfront but increases the risk of premature failure, negating any initial savings. Ultimately, the responsibility lies with the owner or fleet manager to follow the maintenance schedule. That simple act prevents the most common cause of timing belt failure.

Are there warning signs before a timing belt breaks?

Wouldn’t it be great if your car gave a clear signal before the timing belt snapped? Knowing if there are warnings could prevent disaster. So, are there any reliable signs?

Often, there are NO reliable warning signs before a timing belt breaks. While sometimes you might hear ticking noises or notice starting issues, these aren’t guaranteed. Visual inspection during service is the most dependable way to catch potential problems.

Unlike some car problems that give clear hints like strange noises or warning lights, a timing belt failure is often sudden and catastrophic. It’s working one moment and broken the next. Relying on hearing or feeling something wrong is usually not effective.

Why Warnings are Uncommon

Timing belts operate under a cover, making them hard to see or hear clearly. Much of the wear happens gradually inside the belt’s structure (cord fatigue) or as small cracks that don’t necessarily make noise. The belt is under constant tension, so even when weakened, it might run normally right up until the point it snaps or loses teeth. It doesn’t typically stretch noticeably or slip like an accessory drive belt might.

Potential (but Unreliable) Symptoms

In some cases, certain symptoms might indicate a potential issue with the timing belt system (including the belt, tensioner, or pulleys), but don’t count on them:

- Ticking/Rattling Noise: A ticking or rattling sound from the front of the engine could be a failing tensioner or idler pulley bearing, or possibly the belt itself starting to fray and hit the timing cover.

- Engine Won’t Start: If the belt has slipped significantly or broken, the engine likely won’t start. This isn’t really a warning; it’s a sign failure has already occurred.

- Rough Idling/Misfiring: If the belt has jumped a tooth or two, the camshaft timing will be off, leading to poor engine performance, rough idle, or misfires.

- Oil Leaks: Seeing oil leaking from the front of the engine near the timing cover could indicate failing camshaft or crankshaft seals. This oil can contaminate the belt, leading to failure (as discussed earlier). This is more a warning of potential belt damage.

The Power of Visual Inspection

Because audible or performance warnings are unreliable, the best way to assess a timing belt’s condition is through visual inspection. This usually means removing the timing belt cover(s), which can involve some labor. Mechanics often perform this check during major services or when working on nearby components like the water pump (if driven by the timing belt). For buyers like Mark, ensuring their suppliers provide belts that look good and perform well over time is key. We ensure our SANTE belts maintain their integrity, making visual checks more reliable.

What to Look For

During an inspection, you or your mechanic should look for:

- Cracks: Check the back surface and the roots of the teeth for cracks.

- Fraying: Look at the edges for any signs of shredding or excessive wear.

- Missing Teeth: Ensure all teeth are present and look uniform.

- Glazing: A shiny, hardened appearance on the belt surfaces can indicate excessive heat or slipping (though slipping is rare for timing belts unless tension is very low).

- Contamination: Look for signs of oil or coolant saturation.

- Tensioner/Pulley Issues: Check the tensioner for proper operation and pulleys for smooth rotation without noise or wobble.

| Potential Sign | Reliability as Warning | What it Might Mean | Action Recommended |

|---|---|---|---|

| Ticking/Rattling | Low to Medium | Failing tensioner/pulley, belt hitting | Inspect Immediately |

| Rough Idle/Misfire | Low to Medium | Belt jumped time, other engine issues | Diagnose Engine Problem |

| Engine Won’t Start | Failure Indicator | Broken/slipped belt, other issues | Diagnose No-Start Cause |

| Visible Cracks/Wear | High | Belt nearing end of life | Replace Belt Soon |

| Oil/Coolant Near Belt | Medium | Leak contaminating belt | Fix Leak, Inspect Belt |

Don’t wait for a warning sign. Stick to the replacement schedule and perform visual inspections when possible.

Conclusion

Timing belt failure stems from age, wear, contamination, bad tension, or pulley issues. The top cause is simply not replacing it on time. Regular inspection and scheduled replacement are crucial.

-

Learn how pulley misalignment can lead to timing belt issues and how to fix it to avoid engine damage. ↩

-

Understanding replacement intervals is vital for maintaining vehicle performance and preventing costly repairs. Explore this link for detailed insights. ↩

-

Maintaining engine health is crucial for vehicle longevity. This resource provides essential tips for effective engine care. ↩

-

Familiarizing yourself with OEM standards ensures quality and reliability in automotive parts, which is essential for safety and performance. ↩